A plastic injection molding tool is one of the most popular parts for various industries. This article will cover five reasons why plastic injection mold making company is popular.

Cost of the injection molding tool

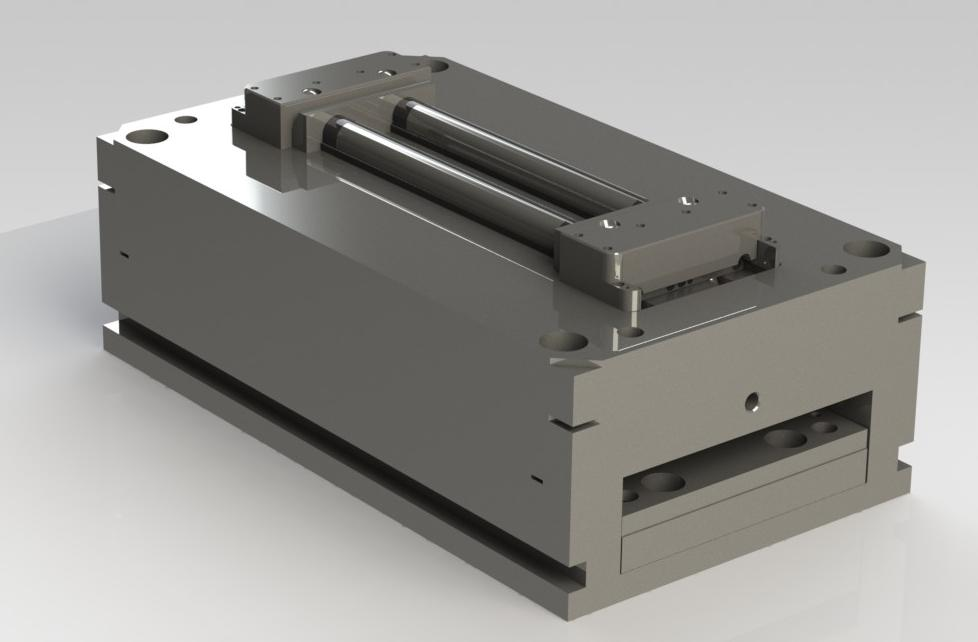

Injection molding is a process that involves making plastic parts, and one of the most costly parts of the process is the tool that is used for this purpose. An injection molding tool is a highly complex piece of machinery that must be carefully constructed. The tool’s cost depends on the size and complexity of the part, the material used to make it, and the time it takes to construct. A larger mold requires more materials and larger machines, and the final price is higher.

An injection molding tool can be used with a variety of materials. Thermoplastic rubber, antistatic plastic, and chemical-resistant plastic are all common types of plastic materials that can be molded using this process. Other materials used in injection molding include infrared biocompatible plastic and antistatic plastics. In addition to standard plastics, this process can also produce parts colored with masterbatch coloring or color compounding. Some injection molding tools can be highly efficient, creating a mold cavity every 10 seconds. However, components with complicated features or specialist materials may take longer. Injection molding can also produce large quantities of mold cavities per hour.

Durability

The durability of a plastic injection mold is determined by its materials and processes. Modern plastics have improved considerably over the years and can withstand harsh environments on par with or better than metal parts. With more than 25,000 engineered materials and high-performance plastic blends, injection molding is possible. For more complex applications, high-performance plastic blends are developed based on the requirements of a specific part. To further improve the durability of your mold, you can consider the material and process that will be used to create it.

Depending on your needs, the material used in the mold must be durable. Steel molds are typically used for mass production, whereas other materials are used for prototypes. Injection molds are durable and can produce thousands of parts without malfunctions. Depending on the part geometry, choosing a mold with a higher durability rating is necessary than the other materials. The durability of the material used in the mold will determine how many parts it can produce and the amount of time it will take to produce each piece.

Versatility

The versatility of a plastic injection mold is dependent on several factors. First, the design of a plastic part must have certain fundamental design elements. These elements include wall thickness, ribs, bosses, corner transitions, weld lines, gate placement, and vents. The strength of the part is a critical factor to consider. Knowing how the part will be used and its environment is also essential.

The material for plastic injection molding is typically thermoplastic. The process complements the versatility of these polymers. Polyethylene plastics are remarkably versatile due to their chemistry. The molecule weight, hardness, and tensile strength of polyethylene plastics are essential characteristics for molding. The resulting parts have a wide variety of properties, making them ideal for the injection molding process.

Speed of production

Injection speed is a crucial parameter in plastic molding, as it affects the material’s properties. The higher the speed, the less a material can adhere to the mold surface, and the higher the risk of voids and defects. Plastics that are too cold will not bond together during the injection. Too high a speed can also lead to blemishes or flashes. Injection speed should be adjusted to minimize these problems.

Traditional mold tooling is created from specialty tooling steels for low-pressure and early prototypes in plastic injection molding; however, emerging technologies allow 3D printed molds to be developed for low-pressure and early prototypes. Once created, mold tooling is expensive to modify, so the design and construction of the tool must be thoroughly thought out. Molders and tool builders need to collaborate closely to ensure the tool design meets the part requirements.